Description

Technical Highlights

-

Raw cellulose: wood pulp or cotton linters – ISO 9001 & 45001 production

-

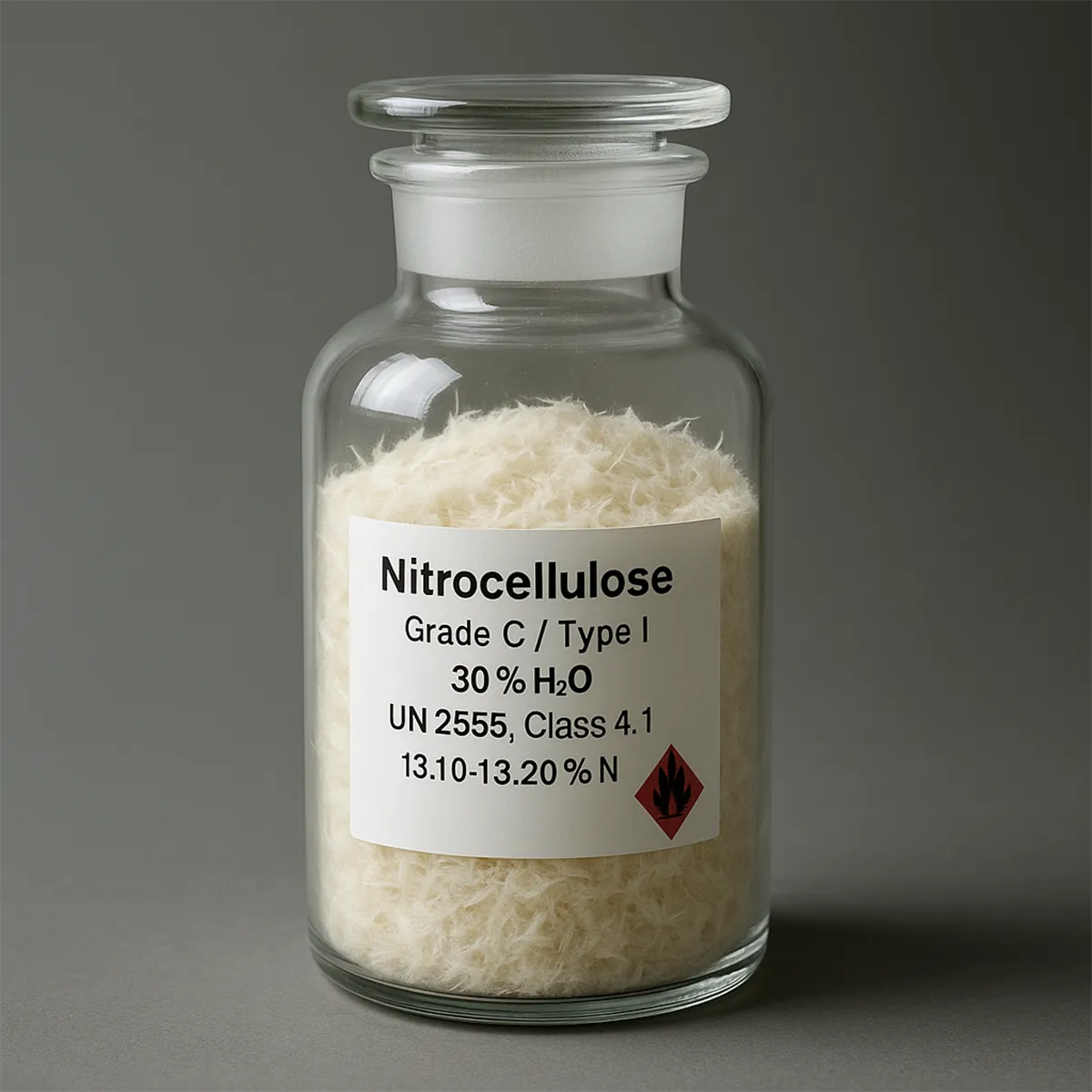

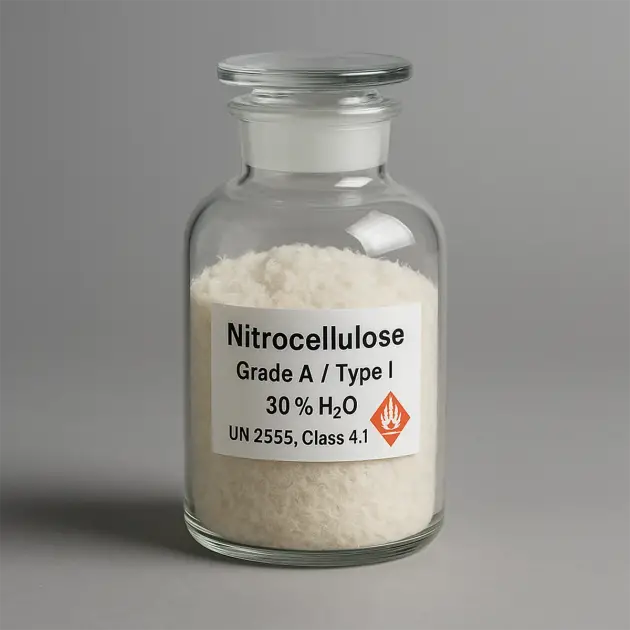

Nitrogen (blend): 13.10 – 13.20 %

• Gun-cotton fibres ≥ 13.35 %

• Pyro-cellulose fibres ≤ 12.65 % -

Viscosity: 9-15 s (falling-ball) • 30-50 mPa·s (2 % in acetone)

-

Moisture as supplied: 27 – 32 %

-

Fineness: 80 – 110 ml / 10 g (dry)

-

Ether–alcohol solubility: 30 – 40 %

-

Bergmann-Junk stability (132 °C): ≤ 2.5 ml NO g⁻¹

-

Standard: MIL-DTL-244C (20 May 2014)

Full Certificate of Analysis accompanies every lot.

Core Applications

Defence & Ballistics

• Single-base powders for rifles, handguns and magnum hunting loads

• Mortar increment charges and bagged artillery propellants

• Low-flash tracer or sub-sonic booster layers

• Igniter formulations for composite rockets

Industrial & Consumer

• Fast-dry nitrocellulose lacquers for furniture, leather and guitars

• High-speed flexographic and gravure printing inks

• Nail-polish film former with superior chip resistance

• Safety-match heads, pyrotechnic binders, speciality adhesives

Safety & Compliance

-

UN 2555 – Division 4.1 (Flammable Solid), Packing Group II

-

Drying, blending or granulation must be performed in licensed ATEX / OSHA explosives facilities.

-

Conforms to MIL-DTL-244C; every shipment is backed by COA and MSDS.