Description

Core Specifications (bullet format)

-

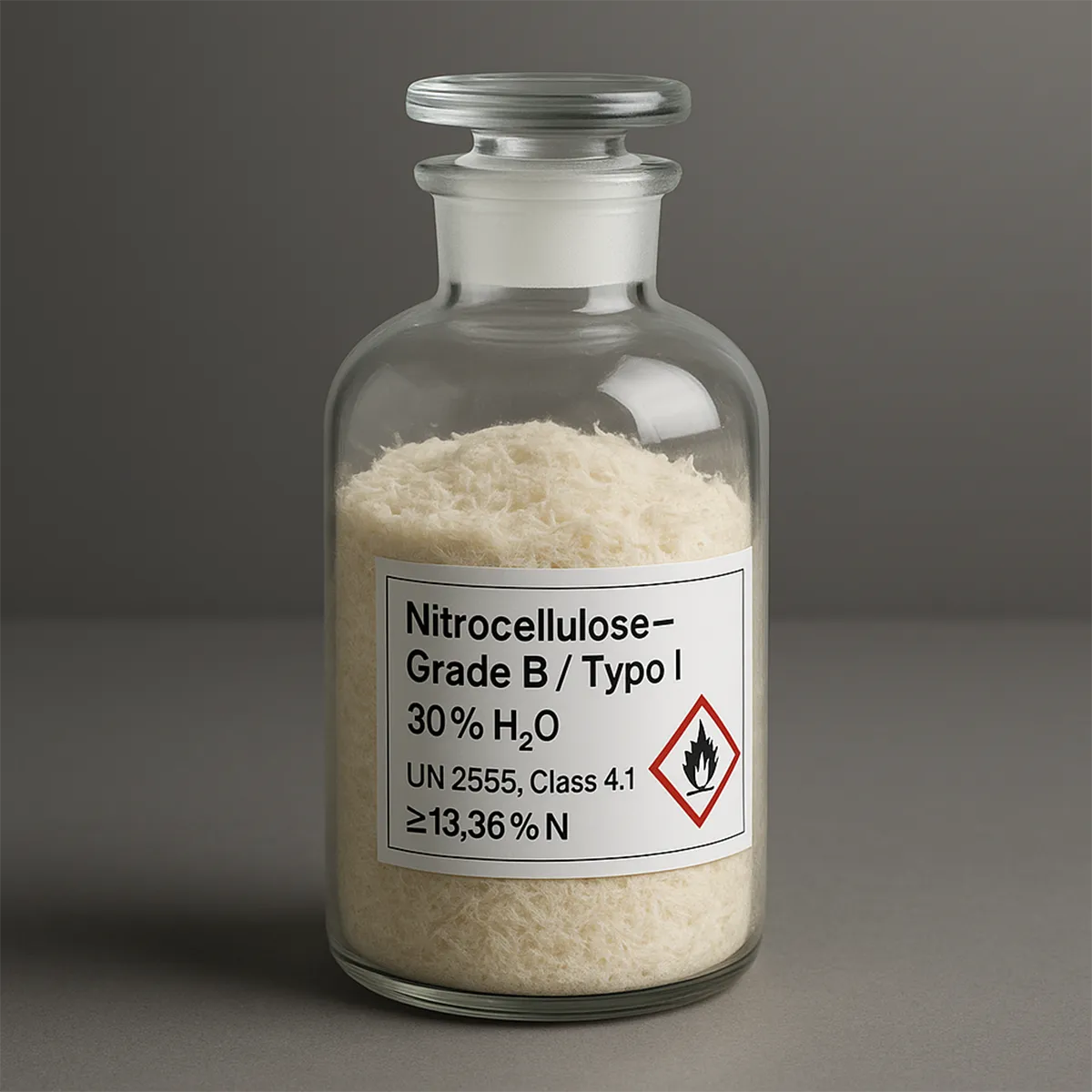

Raw material: wood-pulp cellulose or cotton linters

-

Nitrogen content: ≥ 13.35 %

-

Viscosity (ASTM falling-ball): 9 – 15 seconds

-

Moisture as supplied: 27 – 32 %

-

Fineness: 80 – 110 ml per 10 g (dry)

-

Acetone-insoluble matter: ≤ 0.4 %

-

Bergmann–Junk stability @ 132 °C: ≤ 2.5 ml NO g⁻¹

-

Compliance: MIL-DTL-244C, Amendment 1 (20 May 2014)

Complete Certificate of Analysis ships with every lot.

Defence-Focused Applications

-

Magnum & long-range rifle powders – higher base energy without dual-base nitroglycerine complications.

-

Mortar increment sticks & artillery bag charges – dense gas output for heavy projectiles.

-

Tracer / sub-sonic booster layers – consistent burn at lower chamber temperatures.

-

Igniters for composite rockets – rapid flame spread, low residue.

Industrial Side Uses

Though optimised for ballistics, Grade B can also formulate extra-hard nitrocellulose lacquers, fast-dry leather finishes and high-adhesion flexo inks where greater film strength is needed.

Safety & Compliance Highlights

-

Classified UN 2555 – Division 4.1 (Flammable Solid), Packing Group II.

-

Drying, blending or granulation must occur in licensed ATEX / OSHA explosives plants.

-

ISO 9001 & 45001 certified production; ITAR / BAFA export-control ready.