1. What Is Nitrocellulose Grade?

Nitrocellulose is a thermoplastic polymer produced by nitrating purified cotton linters or wood-cellulose in a mixed acid of nitric and sulfuric acid. During nitration, hydroxyl (–OH) groups on the cellulose chain are replaced by nitro (–ONO₂) groups, giving the material both high flammability and excellent film-forming ability. As nitrogen content rises, detonation velocity and energy density increase; as it falls, solubility improves—ideal for lacquers, varnishes, inks and nail polish in industrial nitrocellulose applications. Its thin, durable film even served as the first movie-film carrier in the late 19th century, though its high flammability also caused the infamous “celluloid fires” of the era.

Quick Facts

- Raw Feedstock: Cotton linters (> 92 % cellulose)

- Nitration Reagent: Mixed acid (HNO₃ + H₂SO₄)

- Nitrogen Range: 10.7 % – 13.6 %

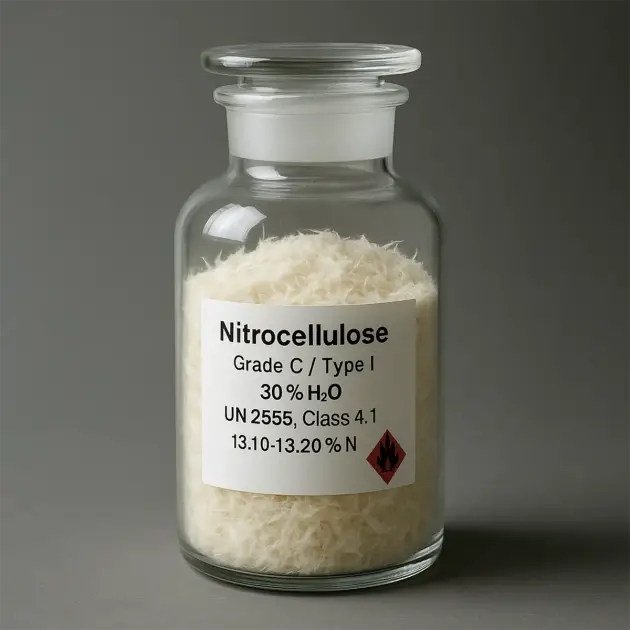

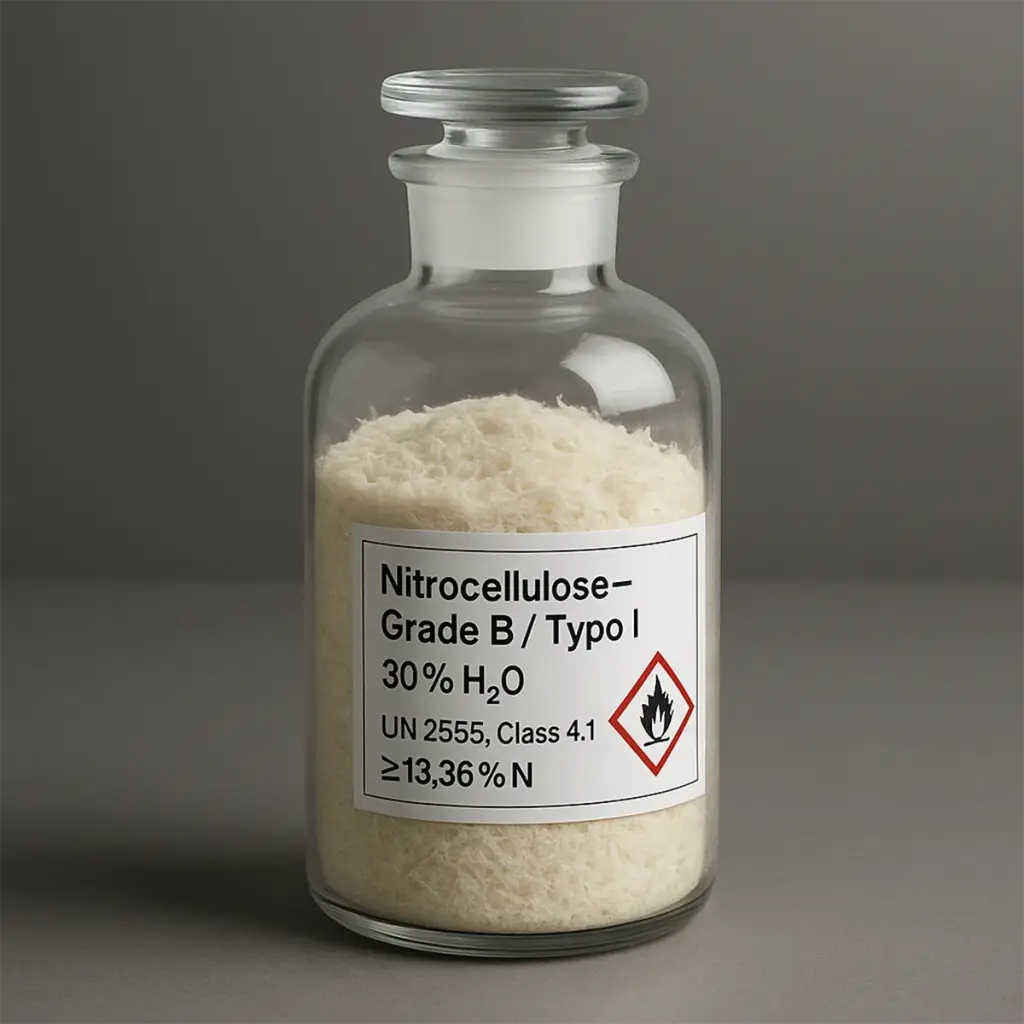

- Physical Form: Pearly flakes or fibrous pulp

- Core Property: Strong, glossy film + easy solubility

2. Classification Criteria

A nitrocellulose grade is defined mainly by its nitrogen percentage and viscosity value. Getting the grade right dictates dissolution rate, film hardness, explosive energy potential and nitrocellulose solvent compatibility.

Viscosity Values

Viscosity is measured (25 °C) in a standard ethanol/ethyl-acetate blend and expressed in CPS.

| Grade | CPS Range | Typical Use |

|---|---|---|

| Low | 0.2 – 1.0 | Nail polish, printing ink |

| Medium | 1.1 – 4.0 | Wood lacquers, furniture varnish |

| High | 4.1 – 10+ | Explosive base, military propellant |

Note: A higher nitrocellulose viscosity value means longer polymer chains—harder films, slower dissolution, and steadier gas release in propellant recipes.

Nitrogen Content & Energy Potential

- 10.7 % – 11.2 % (Industrial Grade): High solubility, low explosive risk; ideal for lacquers, inks, adhesives.

- 11.3 % – 12.2 % (Medium Energy): Pyro-stars, hobby rockets, specialty varnishes.

- 12.3 % – 13.6 % (Explosive Nitrocellulose Grade): Military propellants, primer filler, low-smoke gunpowder.

At 12.6 % N and above, material ships under UN 0340 “Nitrocellulose, wetted” and is classed as an explosive.

3. Grade Selection by Application

Every project demands a different nitrocellulose grade selection. Use this quick reference:

- Furniture Varnish / Wood Lacquer: Medium viscosity, 11 % N.

- Printing Ink: Low viscosity, 11.2 % N; fast drying.

- Nail Polish: Ultra-low viscosity, 10.9 % N; high gloss.

- Pyrotechnic Rocket: Medium-energy, 12 % N; bright spark.

- Low-Smoke Propellant: High viscosity, 13 % N+; controlled gas release.

Balance dissolution rate, film hardness and nitrocellulose solvent compatibility for optimum performance.

4. Solvent Compatibility & Formulation

Nitrocellulose dissolves readily in polar protic (ethanol), esters (ethyl acetate) and ketones (MEK). Viscosity dictates solvent strength: high-viscosity grades need stronger ketone-ester blends, while low grades dissolve in up to 20 % IPA.

Formulation Tips

- 11 % N / 2 CPS → 70 % ethyl acetate + 30 % ethanol

- 12 % N / 5 CPS → 50 % ethyl acetate + 30 % MEK + 20 % IPA

- 13 % N / 8 CPS → 60 % MEK + 25 % ethyl acetate + 15 % acetone

Always use ex-proof mixers and explosion-proof lighting; low flash-point solvents are unforgiving.

5. Storage & Safety Protocols

Nitrocellulose can self-decompose, releasing nitrogen oxides—heat and humidity accelerate the process.

- Temperature: +10 °C – +25 °C

- Humidity: 40 % – 55 % RH

- Packaging: Wet or alcohol-dampened to ≤ 25 % volatile content for hazard reduction.

- Label: “Nitrocellulose, wetted, UN 0340”

- Safety Distance: 40 m (explosive grade)

Even minor violations can trigger auto-ignition; safety is as critical as nitrocellulose grade selection itself.

6. ArrowDefence Solutions & Recommendations

ArrowDefence labs provide viscosity testing, nitrogen analysis and solvent-compatibility mapping to pinpoint the right grade.

- Rapid Viscosity Report: CPS results in 24 h

- Nitrogen Analysis: Kjeldahl + titration

- Formulation Database: 40+ solvent blends

- Safety Training: UN 0340 storage & transport

Tip: Request a viscosity-nitrogen match report for every new batch; intra-batch variance can wreck flow, cure and gloss specs.